Dual fuel engine allow to save fuel expenses where there is easy access to natural gas and travel in the areas without CNG fueling station.

For detailed information press “+” and see detailed chapters

Please read detailed ivformation about ours dual fuel conversion kits:

Dual-fuel engine is ordinary diesel engine which is equipped with additional CNG supply units.

In dual-fuel mode engine is supplied by 2 fuels: primary diesel fuel (but in sufficiently less amount) and additional CNG fuel. In this case diesel fuel dose acts as fuse for air-fuel mix inflammation.

Fuse fuel is necessary for air-fuel mix inflammation. Methane comparing with diesel fuel has sufficiently higher combustion temperature, that’s why single methane cannot combust at standard diesel cycle conditions without spark plug.

That’s why some diesel fuel is injected in cylinder at the end of compression stroke, with the goal of inflammation of gas-air mix which enter into cylinder at the inlet stroke.

Dual-fuel engine can work using diesel fuel only, but cannot use 100% CNG.

Most important dual-fuel engine index is diesel fuel by CNG fuel substitution coefficient, your cost saving depends on it.

Substitution coefficient value can vary from 40% to 60% for methane and from 15% to 35% for propane-butane. Exact value depends on diesel fuel supply system, dual-fuel system quality and your driving style even (see picture below).

The point is following: when engine starts and works in low load regime (up to 30% of max load) it is fueled by diesel engine only almost, because there is very difficult to provide reliable CNG supply regime.

Then with load increasing (up to 70-80% of max load) there is most favorable for CNG zone, substitution coefficient is maximal and can reach 95% theoretically.

But with the goal of engine heating regime keeping in a due frame, it is necessary to leave 20-30% diesel fuel at least for fuel injectors and valves cooling.

When engine works at full load and rpm is highest, working cycle time decreases, CNG have not time to be burnt and dual-fuel EMS need to decrease CNG supply.

For practical estimations you can admit guaranteed substitution coefficient in 50% for methane engines and 40% for propane engines. Bigger substitution coefficient is possible, especially with right driving style, but not guaranteed.Dual-fuel engine efficiency is 5-7% higher than efficiency of original diesel engine. This can be explained by external air-fuel mix formation in dual-fuel engine, which results in homogenous mix formation in intake collector. It allows to use less air-fuel ratio which results in better fuel efficiency and under certain conditions provide 20-30% power increasing comparing with original diesel engine.

Because of higher efficiency, CNG consumption in nm3 is equal 0,9-1 x substituted diesel fuel consumption in liters.

Your fuel expenses saving value is equal to difference between 100 km diesel fuel expenses before conversion and 100km CNG + diesel fuel expenses after.

For example, in Scania R380 6×4 (load 14 tons) diesel fuel average consumption is 43L/100km, when after dual-fuel conversion diesel fuel consumption is decreased up to 28L/100km plus 12nm3 of CNG. methane average consumption comes out at 42 nm3. Taking into account 31 roubles (1 USD) diesel fuel price 100km trip cost is 41,6 USD, and after conversion with 12,3 roubles (35 cents) per 1 nm3 methane price, 100 km trip cost is 31,8 USD. All prices are based on Russia prices at the end of 2013.

Saving is 9,8 USD or 25% approximately. Taking into account 120 000km annual mileage, annual saving is 11 709USD. Dual-fuel equipment cost is 7 096 USD. So cost return period is 6 months.

Dual-fuel conversion doesn’t demand serious engine modification. We just install additional equipment: CNG supply system, sensors and control system. How does it look:

Dual-fuel system core is ECU ( Electronic Control Unit ). It receives various sensors signals, basing on them ECU issue output signals for diesel fuel and CNG supply control. Concrete signal set depends on diesel fuel supply equipment type and concrete dual-fuel system modification. For example sensors set can be like below:

- Oxygen sensor

- Electronic accelerator pedal sensor (PPS)

- Oil temperature sensor

- Diesel fuel pressure sensor

- Knock sensor

- RPM sensor

- CNG pressure sensor

- Manifold pressure sensor (MAP)

While conversion of common rail diesel engine it is possible to exchange data between original diesel fuel ECU and dual-fuel ECU using CAN interface.

Injectors are screwed in inlet manifold, they inject CNG according to ECU signals and in diesel fuel supply line controlled by ECU actuator valve is mounted for diesel fuel supply mechanical limitation.

Actually that’s all!

Main engine characteristics (power, max torque, torque-rpm curve, noise, exhaust gas temperature) in dual-fuel engine strongly depends on substitution coefficient value and can be both higher and lower comparing with initial diesel engine.

Under recommended by us substitution coefficient value (50% for mechanical diesel fuel injection system, 60% for electronic diesel injection system) main engine characteristics will NOT CHANGE.When placing order we can according to your wishes both increase engine power in dual-fuel regime up to 10-20% and decrease it to the same value. Substitution coefficient will be respectively increased or decreased in the same scale.

Because of possible engine cooling problem when working with increased power in dual-fuel regime, we recommend to consider power increasing with due caution.

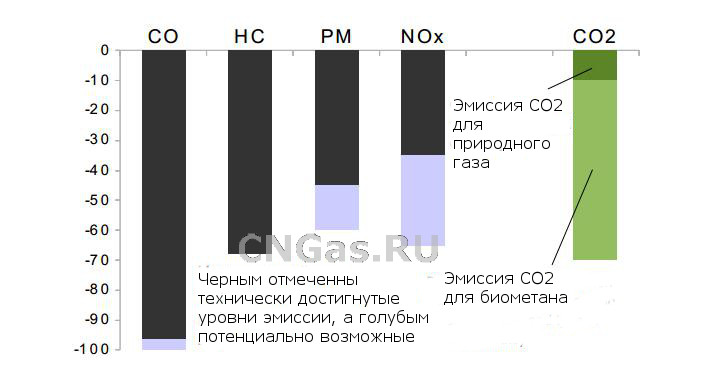

Dual-fuel engine has much more better emission values comparing with diesel engine.

Emission degree depends strongly on engine working regime and substitution coefficient.

According to European Natural gas vehicles association, with 50% substitution coefficient, emission decrease values are following:

Give my price !

Give my price !