We can convert practically any diesel engine to 100% CNG.

Don’t wait, start to save costs from today!

Diesel engine is engine where fuel combustion is performed when heating under the pressure applied. Standard diesel engine couldn’t use CNG fuel, because methane comparing with diesel fuel has sufficiently higher combustion temperature (diesel fuel 300-330 C, methane 650 C) which cannot be gained with compression ratio present in standard diesel engine.

Second reason preventing CNG fuel usage in diesel engine is detonation, i.e. improper, burst-like fuel combustion which occurs when excess compression ratio is applied. In diesel engines is used fuel-air mix 14-22 compression ratio when methane engine should have ratio of 12-16.

That’s why for 100% diesel-CNG conversion two main procedure should be done:

- • Decrease compression ratio

- • Install spark ignition system

After abovementioned procedures accomplishing your diesel engine will use CNG only. Diesel fuel usage recovery is possible after additional works done.

More detailed description of our scope of works you can find in the chapter ‘How actually go about diesel to CNG conversion? ’

Your fuel expenses saving value is equal to difference between 100 km diesel fuel expenses before conversion and 100km CNG fuel expenses after.

For example, in Fredliner Cascadia case diesel fuel average consumption is 35L/100km, when after 100% CNG conversion methane average consumption comes out at 42 nm3. Taking into account 31 roubles (1 USD) diesel fuel price, 100km trip cost is 35USD, and after conversion with 11 roubles (35 cents) per 1 nm3 methane price, 100 km trip cost is 15USD. All prices are based on Russia prices at the end of 2013.

Saving is 20USD or 57% of initial expenses. With 100 000 km annual trip, annual saving is 20 000 USD. Fredliner conversion full expenses (including CNG system parts, CNG cylinder, installation works, engine processing etc.) was 600 000 roubles (19 300 USD). ). So as you can see, money back period is 11 months approximately.

Methane additional advantage is easy consumption control: it is virtually impossible to steal and sell compressed at 20 MPa gas.

You can calculate CNG consumption after conversion basing on the 1,05 -1,25 ratio of methane nm3 to diesel fuel liters of previous consumption (it depends on diesel engine features, its depreciation stage etc)

Examples of methane to diesel fuel ratios for converted by us various diesel engines you can read here.

For preliminary calculation you can assume average ratio 1 L diesel fuel before conversion = 1,2 nm3 CNG after.There are more than 500 CNG fueling stations in CIS countries, and more than 240 station in Russia alone.

You can get up-to-date information regarding CNG fueling stations dislocation and working regime at the interactive map below. Map is kindly supplied by web-site gazmap.ru

If your company has more than 30-50 vehicles, so it is wise to consider vehicle fueling at your company territory with the help of mobile CNG storage. More information about our mobile CNG storages you can find here

And if there is natural gas pipeline running close to your company, so we can consider own CNG fueling station building.

Just call us and we gladly consult you about all variants possible!

Vehicle-borne methane is stored in the special cylinders in the gaseous state under high pressure of 200 atm. Big weight and size of those cylinders is sufficient negative feature placing serious restriction to CNG usage as vehicle fuel.

Our company uses high-quality metal-plastic composite cylinders (Type II) tested and certified according to Russian standards.

Internal part (so called ‘liner’) is actually metal cylinder made of chrome-molybdenum steel, external part is fiberglass wrapping fixed with epoxy.

For methane 1 nm3 storage 5 liters of actual (so called hydraulic) cylinder volume is necessary, for example 100-liters cylinder can store around 20 nm3 of methane (a little bit more actually because methane is not ideal gaseous matter and has better compression ratio).The weight of 1 liter of cylinder volume is around 0,85 kg, so total weight necessary for methane 20 nm3 storage is around 100 kg (85 kg is empty cylinder weight, 15 kg methane weight).

Here is a picture of type 2 composite cylinder:

Assembled methane storage system:

Practically we can reach following runs and weight:

- 200-250 km — for small buses. Storage system weight — 250 kg.

- 250-300 km —for middle-size city buses. Storage system weight — 450 kg

- 500 km— for tractor trucks. Storage system weight — 900 kg

Diesel engine to CNG conversion needs serious modification of engine parts.

At first we need to change compression ratio (What for? See chapter “How diesel engine can use methane?”). We use various ways to do it, choosing the best one suitable for your engine:

- Pistons milling

- Additional cylinder head laying

- New pistons manufacturing

- Connection rods shortening

In most cases we use pistons milling (see picture above).

Pistons after milling will be like that:

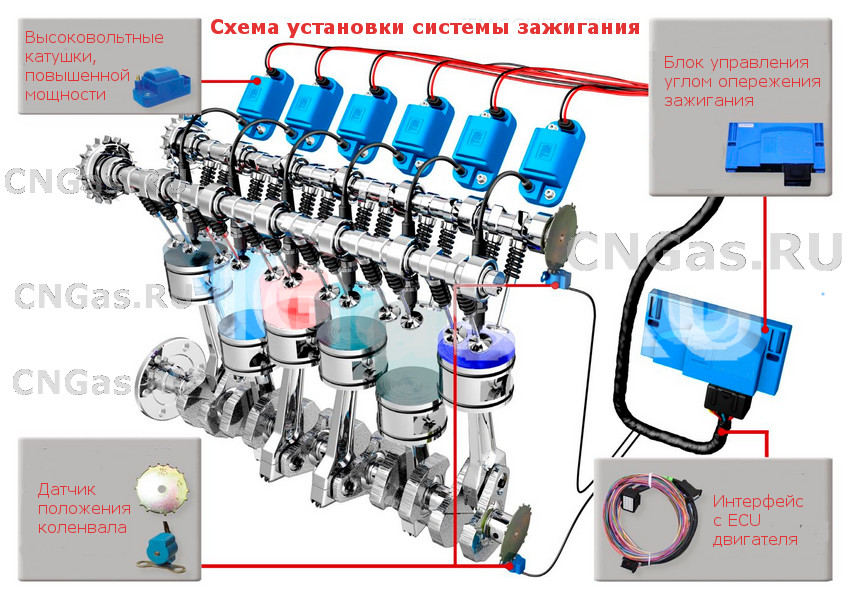

Than we install system of gas injection through special nozzles and spark ignition system. (What for? See chapter “How diesel engine can use methane?”).

We also install few additional sensors and devices (PPS, CAM sensor, oxygen sensor, MAP sensors etc.)

All components are controlled by Engine control unit (ECU).

Conversion kit components:

For modern turbocharged diesel engines it is not true.

High strength durability of original diesel engine designed for withstanding of 16-22 compression ratio, combined with methane high octane number, allows us work at 12-14 compression ratio, doing possible to achieve the same and even higher engine power using stoichiometric fuel-air mixture. But under those condition emission standards higher Euro-3 complying is not possible, also we got converted engine thermal load increasing.

Modern turbocharged diesel engines (especially with air intercooling) allows us to use sufficiently lean air-fuel mixture saving initial diesel engine power, keeping thermal load under control and stay within emission Euro-4 standard.

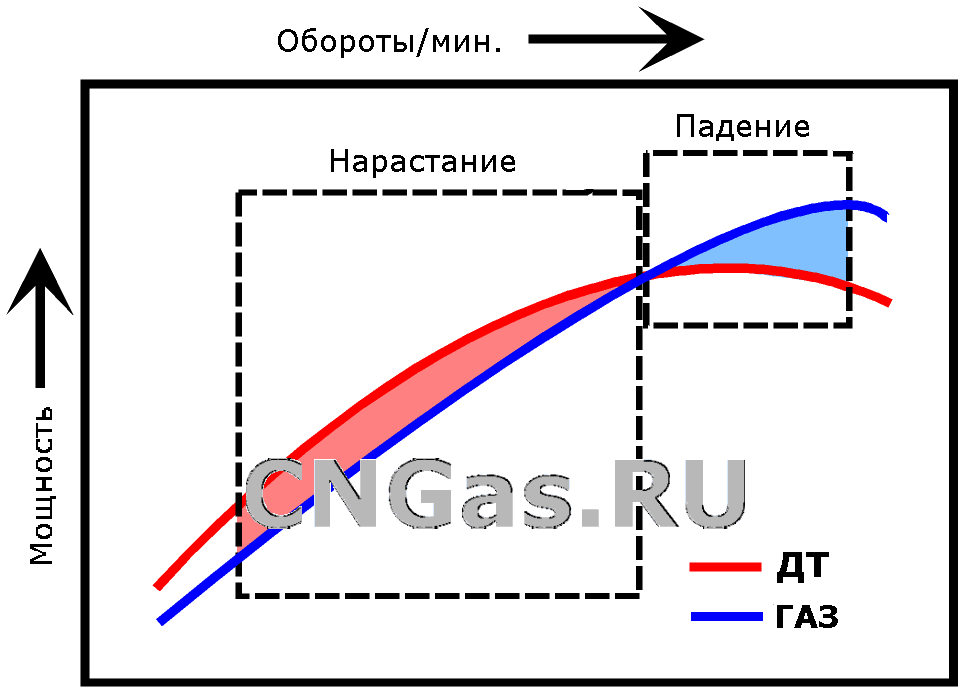

Typical power –rpm function, with different fuels:

TorqueMax torque value doesn’t change and may be becomes increased even. But max torque point shifts to the higher rpm area. It isn’t so pleasant, but according to our experience, drivers don’t complain and get accustomed quickly, especially in the case they got more power capacity..Decisive solving of max torque shift problem in the CNG engine can be achieved by original turbine replacing by special oversize turbine with EM bypass valve for high rpm. But high cost of this solution doesn’t allow us to use it while single individual conversion is done.

ReliabilityEngine durability is increased sufficiently. Because of methane combustion is more even comparing with diesel fuel, because compression ratio is less and because CNG don’t contain various impurities like diesel fuel. Engine oil CNG engines are more demanding to engine oil quality. We recommend to use high-quality all-season oils SAE 15W-40, 10W-40 types and change oil every 10 000 km at least..If it is possible, better use special oils like Lukoil Efforce 4004 or Shell Mysella LA SAE 40. It is not obligatory, but using those oils brands engine life will be prolonged.

Because of higher water content in gas-air combustion exhaust product, engine oil water-resisting properties are a matter of question, also CNG engines are more sensitive to ash formation in combustion chamber. That’s why sulfate ash-content of engine oil for CNG engines is limited by lower values, while water-resistance demands are higher.

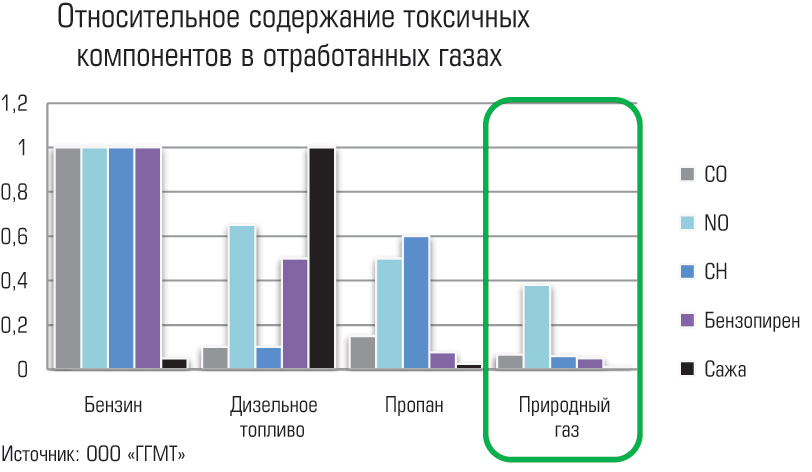

NoiseYou will be amazed! CNG engine is very silent machine comparing with diesel-fueled one. Noise level decreases up to 10-15 dB according to measurement, which means 2-3 times less noise according to subjective feeling.CNG engine ecological parameters sufficiently exceed its diesel analog and give way to electric and hydrogen engines only.

It can be clear visible when comparing exhaust smoking, the most important factor at big cities. Smoke tale of diesel buses is the biggest annoying feature of public transportation in cities. CNG engines are free of this disadvantage because there is no ash when methane combustion.

CNG engine emission standard is Euro-4 (without carbamyde or exhaust gas recirculation), but it can reach Euro-5 when installing additional catalyzer.

| Parameter | Light truck, mini-bus | Dump-truck, medium-duty truck, medium bus | Heavy duty truck, big bus |

|---|---|---|---|

| Cylinders | 4 | 4-6 | 6-8 |

| Engine power, h.p. | 50-150 | 150-250 | 250-700 |

| CNG storage system volume, nm3 | >40 | >60 | >100 | CNG system (underhood equipment only) cost, USD | >8500 | >10 000 | >11 000 |

| CNG storage system cost, USD | >2000 | >3000 | >5000 |

| Conversion time (certification time not included), days | 5-10 | 7-12 | 10-15 |

| Total conversion cost, USD | >10 500 | >13 000 | >16 000 |

Give my price !

Give my price !